Sample Product photograph:

1.Work process description:

The proposed system is expected to read all standard barcode topologies from top, left and right (according to the specifications given earlier), capture and store high quality images of goods (should be able to read AWB # from the images), measure dimensions (length, width and height) in centimeters, and the actual weight in kilograms of cubic and non-cubic goods passing through the moving conveyor.

If the dimensions or weight or AWB number on the barcode are measured incorrectly, the system should stop and alert the operator with a red tower light and an audible alarm. Errors should also be displayed on the operator touch screen panel, prompting the operator to clear the error. After clearing the error, the machine should start automatically.

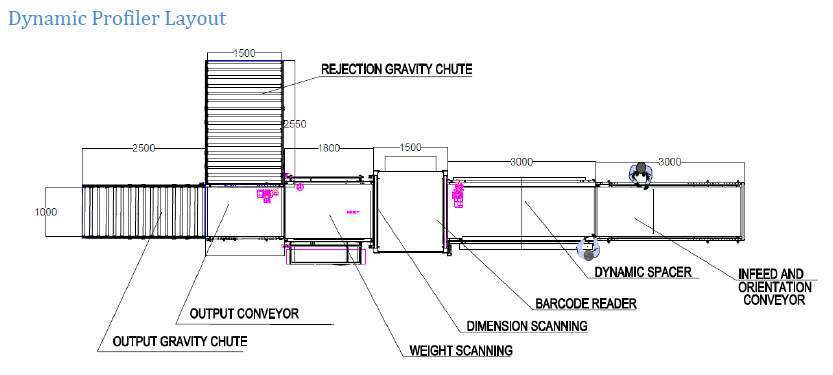

2. System layout diagram:

- Ordering Specifications:

| Property | Value |

| Length • Minimum • Maximum • Accuracy | • 100 mm • 1200 mm • +/- 5 mm |

| Width • Minimum • Maximum • Accuracy | • 50 mm • 900 mm • +/- 5 mm |

| Height • Minimum • Maximum • Accuracy | • 5 mm • 900 mm • +/- 5 mm |

| Design Throughput | 1800 PPH at a product Size of 1200X900X 900mm |

Rejection System Conveyor Stop with Alarm and red light blinking

Output System Gravity roller conveyor

User Interface 15” Touch screen based PC to display barcode number, Length, Width, Height, Actual Volume, Box Volume and Actual Weight

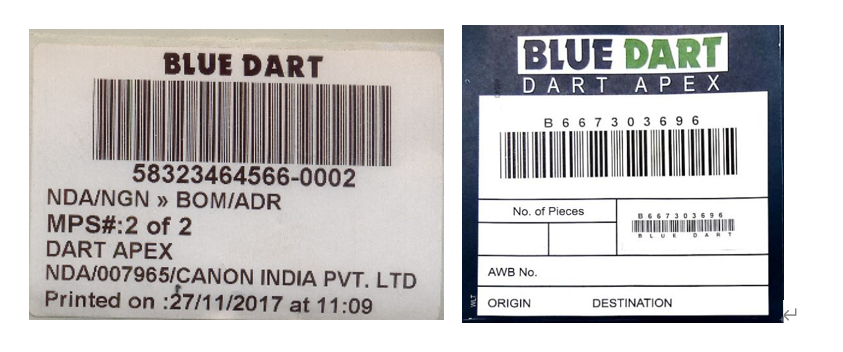

3.Barcode details

| Label | Barcode | ||||

| H[mm] | W[mm] | H[mm] | W[mm] | Barcode type | |

| Type 1 [Thermal printed] | 60 | 90 | 19 | 69 | Code 39 |

| Type 2 [Thermal printed] | 100 | 100 | 18 | 65 | Code 128 |

| Type 3 [Pre- printed] | 120 | 120 | 20 | 88 | Code 39 |

4.Sample Barcode

- Safety :

The proposed system should be equipped with necessary emergency stop button near the infeed conveyor which should stop the machine when pressed.

- Documentation:

The system should be supplied with operation manual and maintenance manual (2 copies each) in English language.

- Training :

The machine manufacturer must provide training to Blue Dart Representatives after successful installation of the machine on machine operation, maintenance and basic trouble shooting.