The high-volume production and high-quality standards of the automotive industry require continuous innovation of production systems. Improving efficiency, reducing downtime and ensuring operator safety are key to success.

The key to satisfying today’s fierce automotive industry. Noppze modular belt conveyor equipment provides innovative conveying solutions for automotive production, processing and parts.

• Car repair and painting

The use of Noppz modular crawler conveyor equipment in anti-skid conveyors increases the reliability of the conveyor line and reduces maintenance and unexpected downtime. In the event of a malfunction, the crawler conveyor can easily replace damaged modules in the shortest possible time and without the use of complex tools. The modular track adopts low friction

The free silicon material requires no lubrication, effectively reducing noise, saving energy consumption, and extending the service life of all conveying components. Anti-static materials are more suitable for applications in factories where employees come into contact with tapes.

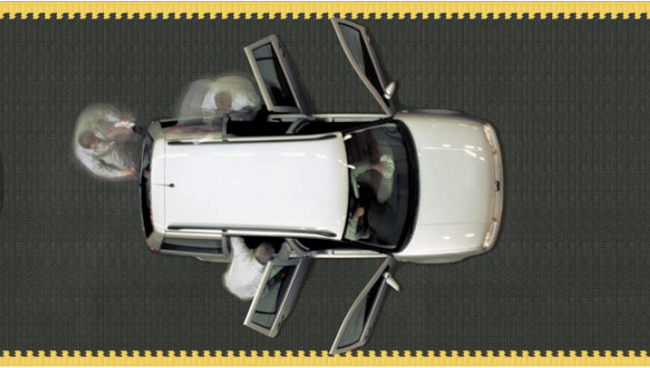

• Assembly bus and rain shower quality control line

Noppze modular track conveyors are conveyors specifically designed for final equipment and quality control to move people and vehicles. The manned vehicle and modular crawler tracks ensure efficient and comfortable transportation of operators while providing a stable and safe working platform. Special non-slip work surfaces allow operators to move around safely even in the presence of water. Among them, the perforated anti-skid crawler track is specially designed for the underwater test line. The perforated surface facilitates drainage and provides a safe conveying surface. Non-slip modular tracks for loading and unloading areas, product sorting and body shops.