Knife-edge belt conveyor is an advanced conveying equipment widely used in various industries. It has the advantages of high efficiency, high precision and high flexibility, and provides a more efficient, stable and reliable conveying method for the production process. Below we will introduce in detail the advantages and production methods of knife edge belt conveyors.

Advantages of knife edge belt conveyor

1. High efficiency and stability

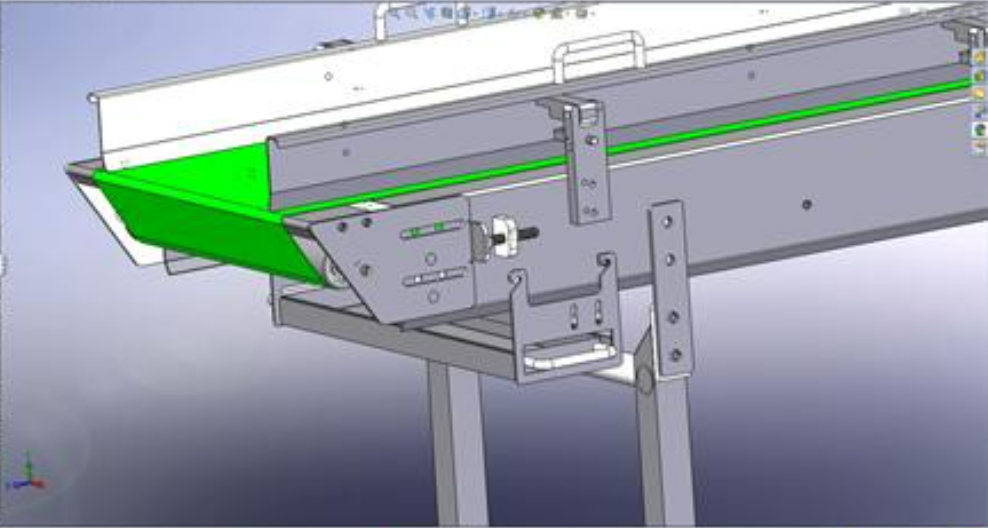

Compared with traditional conveying equipment, knife-edge conveyors have higher conveying efficiency and smoothness. It uses a knife edge for conveying, which can adapt to items of various shapes and specifications and has high flexibility. At the same time, the conveyor belt of the knife-edge conveyor is made of high-strength materials, which can withstand large weight and impact force, ensuring the smoothness and stability of the conveying process.

2.Wide scope of application

Knife edge conveyors are widely used in various production lines and processing processes, such as food, metal, logistics and other industries. In the food industry, knife edge conveyors can be used for smooth transportation, packaging and processing of food; in the metal industry, they can be used for transportation, grinding and processing of metal materials; in the logistics industry, they can be used For operations such as sorting, packaging and transportation of goods.

3. Simple structure, easy operation and low maintenance cost

The knife edge conveyor has a simple structure, high reliability of each component, and is very convenient to maintain. In daily use, you only need to regularly check key parts such as the blade and bearings to ensure their normal operation. In addition, the operation of the knife edge conveyor is simple and can be mastered quickly without the need for professionals. Therefore, its maintenance costs are relatively low and can save companies a lot of operating costs.

The process of making a knife edge belt conveyor :

1. Design stage

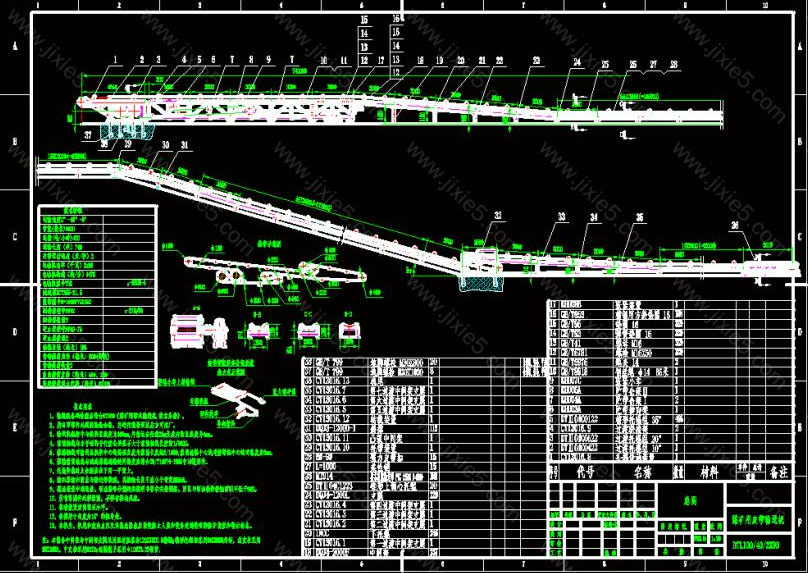

Before making a knife edge belt conveyor, the design phase needs to be carried out first. Designers need to determine the conveyor’s conveying length, width, height, conveying speed and other parameters based on actual needs and uses, and select appropriate conveyor belts, driving devices, transmission rollers, redirection rollers, idlers and other components. At the same time, factors such as the structural stability and safety of the conveyor also need to be considered.

Knife edge conveyors are widely used in various production lines and processing processes, such as food, metal, logistics and other industries. In the food industry, knife edge conveyors can be used for smooth transportation, packaging and processing of food; in the metal industry, they can be used for transportation, grinding and processing of metal materials; in the logistics industry, they can be used For operations such as sorting, packaging and transportation of goods.

Simple structure, convenient operation and low maintenance cost

The knife edge conveyor has a simple structure, high reliability of each component, and is very convenient to maintain. In daily use, you only need to regularly check key parts such as the blade and bearings to ensure their normal operation. In addition, the operation of the knife edge conveyor is simple and can be mastered quickly without the need for professionals. Therefore, its maintenance costs are relatively low and can save companies a lot of operating costs.

2. Production stage

After the design phase is completed, you can enter the production phase. During the production process, it is necessary to process and assemble according to the design drawings. First, the frame and bracket of the conveyor need to be made, and then the conveyor belt is installed and debugged. When installing the conveyor belt, you need to pay attention to the tension and offset of the conveyor belt to ensure the smoothness and stability of the conveying process. Next, the installation and debugging of the driving device and transmission roller are required to ensure the normal operation of the conveyor. Finally, comprehensive inspection and testing are required to ensure that the conveyor’s various performance indicators meet the requirements.

3. Adjusting stage

After the production is completed, the debugging phase needs to be carried out. During the debugging process, various functions of the conveyor need to be tested and verified, such as the running speed, tension, offset, etc. of the conveyor belt. At the same time, the safety performance of the conveyor also needs to be tested, such as protective devices, emergency stopping devices, etc. During the debugging process, problems found need to be dealt with and improved in a timely manner to ensure the normal operation and safety of the conveyor.

In short, the knife edge belt conveyor is an advanced conveying equipment with the advantages of high efficiency, high precision, high flexibility, etc., and is widely used in various industries. Its production method includes the design stage, production stage and debugging stage. It needs to be processed and assembled in strict accordance with the design drawings and process requirements, and comprehensive inspection and testing are carried out to ensure that the various performance indicators of the conveyor meet the requirements.

Please keep in touch with Noppze Conveyor if you want to get more information about PU or PVC belt of Knife edge conveyor .